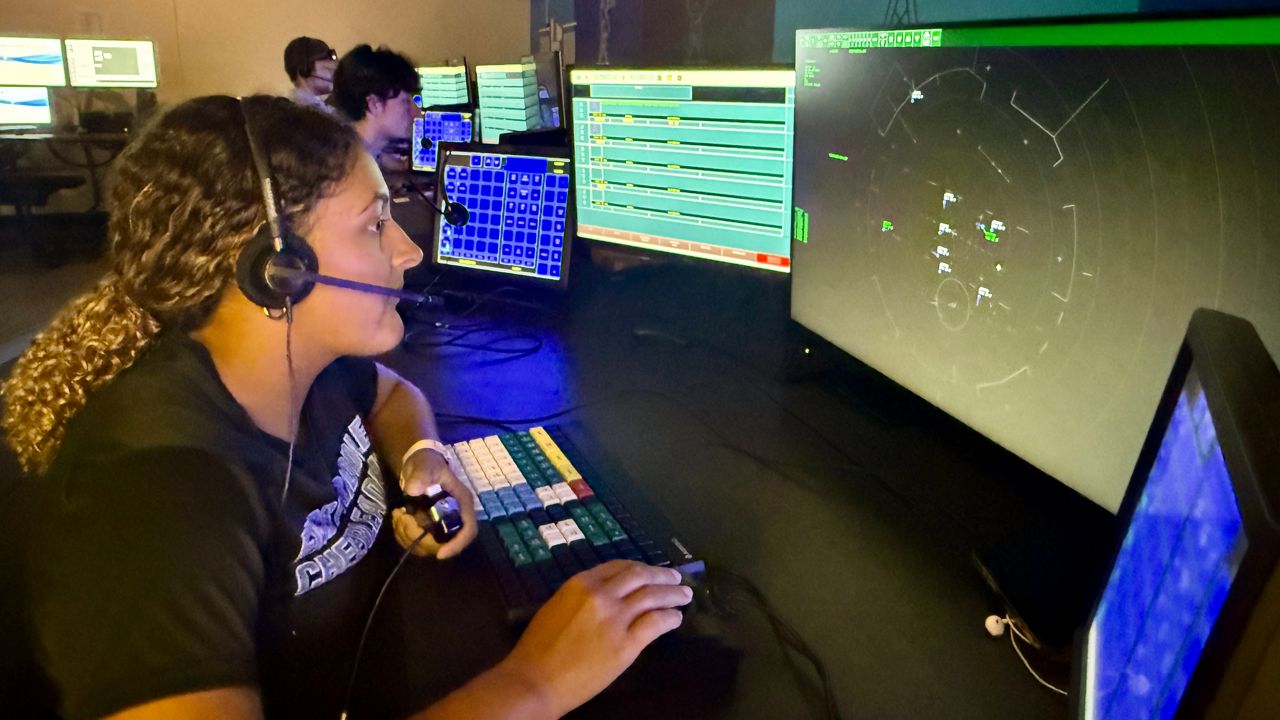

PALM COAST, Fla. — It doesn’t matter if it’s a refrigerator, microwave, washer or dryer. They all have a common and important part, a capacitor.

It’s something one Palm Coast company is full steam ahead in manufacturing, regardless of any global uncertainty.

What You Need To Know

- AmRad Manufacturing moved to Palm Coast from the Northeast in the 1980s

- 90% of materials in the capacitors made from U.S.-made companies and materials

- The company is hoping to be using 100% U.S.-made materials by 2027

AmRad Manufacturing has been around since the 1939, but has been making capacitors in Florida since the 1980s.

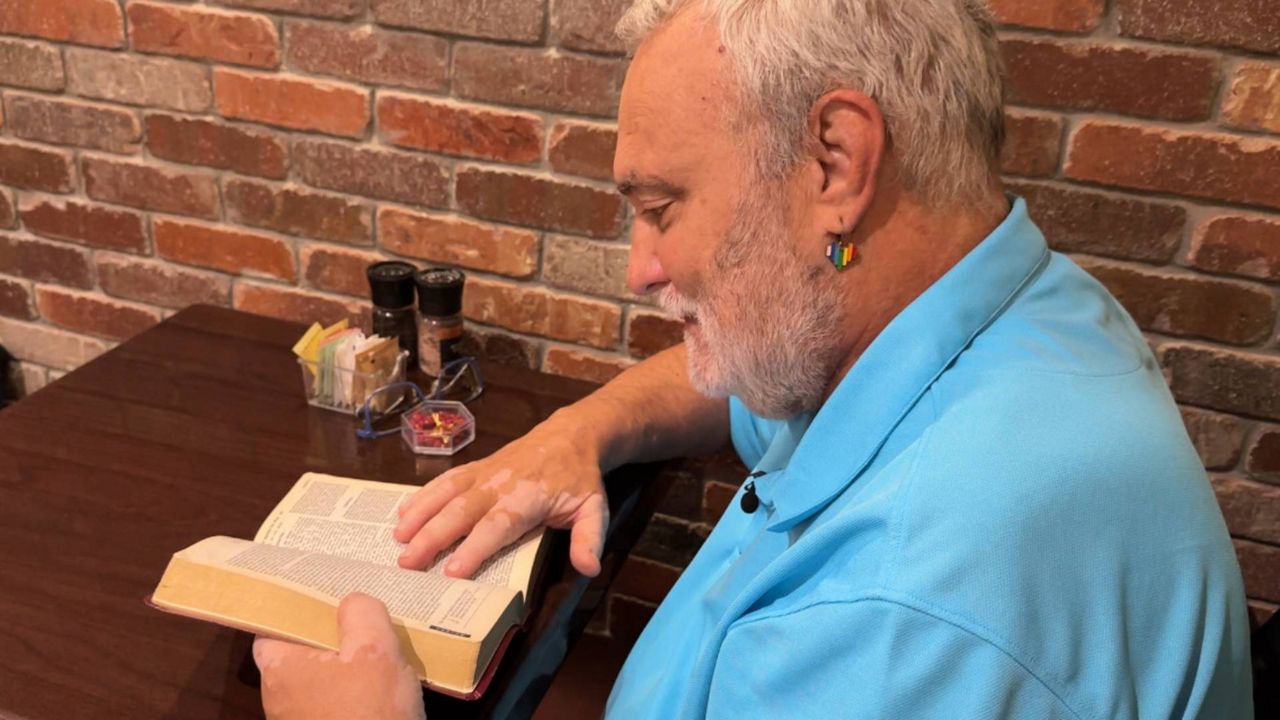

Their product costs more than their competitors, about three to four times more than what a consumer would find on big box shelves, but there’s a reason for that.

Aside from staffing, they try to get as much materials as they can from U.S.-based companies.

“It’s all about the quality,” AmRad Manufacturing Plant Manager Gary Winter said. “We have probably over 100 different steps from the time the raw materials enter our facility till that product goes out the door where we check quality. We really don’t worry about cost here, it’s about quality.”

Nearly 90% of the materials they use to make their capacitors come from the U.S.

The one piece that’s not made or from the country is their capacitor covers, but that could change soon.

Chief engineer at AmRad, Jerry Waldrop, says right now the company is looking into making covers for their capacitors in-house by 2027.

“As far as the simple covers, probably within six months to a year,” Waldrop said. “The complex ones — I would say another year past that.”

Throughout the year, AmRad has about 100 employees working four days a week, and turns about 2 million capacitors a year.

If production needed to be ramped up, or demand reached record highs, Winter says they have the capability to produce 8 million a year.