CLEVELAND — Washing machines are among the top contributors to microplastics in the environment, accounting for 35% of microplastic pollution, according to the International Union for the Conservation of Nature.

Lake Erie has the second highest concentration of plastic among the five Great Lakes despite being the smallest, according to the Lake Erie Foundation. One company based out of Case Western Reserve University in Cleveland is hoping to help solve that problem by changing the way washing machines are filtered.

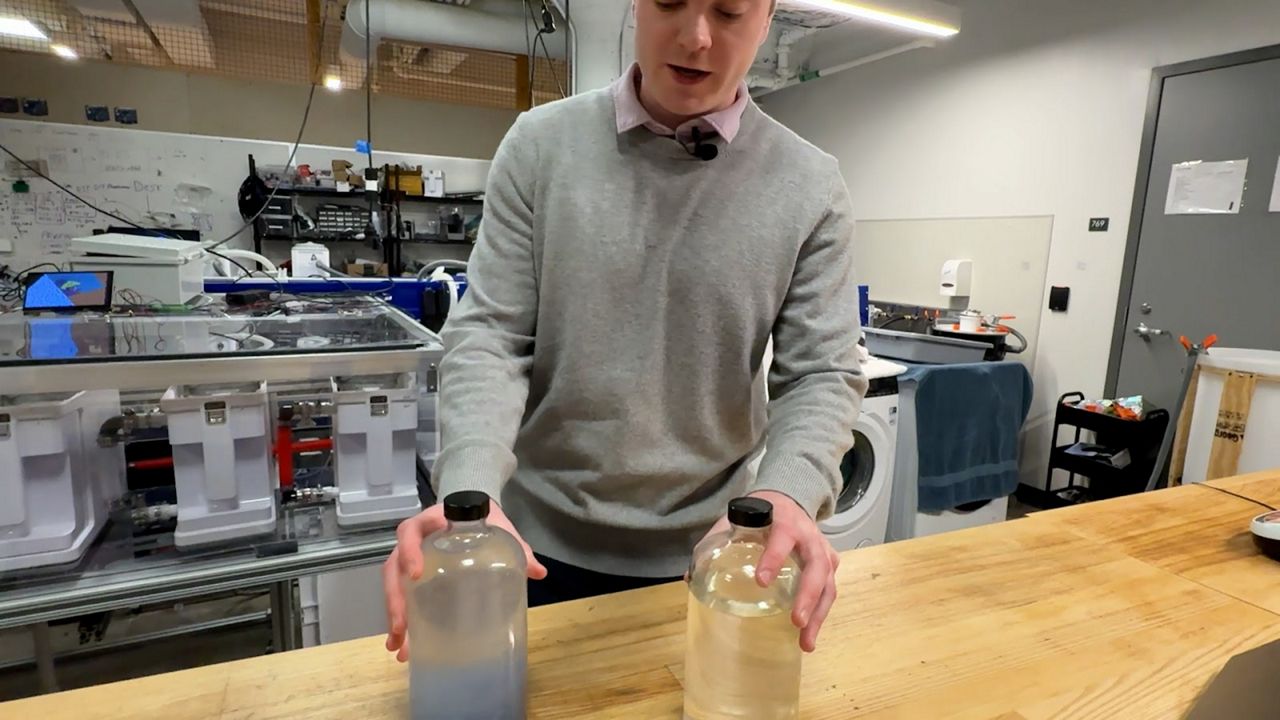

“We really want to show that there is something you can do about it," CLEANR CEO and co-founder Max Pennington said. "“The microfibers from our clothing that are shedding as they’re being washed are basically ending up in our food and in our water and ultimately back in our bodies.”

Pennington is the CEO and one of three co-founders of CLEANR, a company founded by Case Western Reserve University graduates and run out of the university, that's trying to address that issue. They’ve developed a filter, largely inspired off the inside of a fish’s mouth, to help eliminate microplastics in the wash cycle.

“On the inside of a fish’s mouth, they generate a vortex to keep their gills from clogging," Pennington explained. "We use a similar principle that basically generates a vortex all the way down the spiral geometry to keep our mesh from clogging. Our filter itself can basically attach to any washing machine and remove 90% of microplastics down to 50 microns in size.”

Pennington co-founded the company after interning at Procter and Gamble. He brought the idea to his two fraternity brothers Chip Miller and David Dillman, and CLEANR was born. Miller says they didn’t realize the magnitude of microplastic pollution in laundry until they started their research.

"We didn’t realize how big of a problem this was until we started to see how many fibers and all the plastics that are really in the water," CLEANR COO & co-founder Chip Miller said.

Like most startup companies, there were bumps in the road along the way.

"We actually flooded my apartment three years ago when we had the simple forms of filtration," Pennington said.

The co-founders agree that the company has come a long way as its product gets set to hit the market and they hope that the continue to make a positive difference in the environment.

"Three years ago we found out about this big problem and said we want to figure out how to solve it," CLEANR CTO and co-founder David Dillman said. "When we flooded Max's apartment what the filter looked like was a tiny tube with a little disk. It's crazy to look back at where we started and how much we’ve done in three years and how much we’re going to do on the microplastic problem moving forward.”

![CLEANR is ran out of the Sears think[box] on Case Western Reserve University’s campus.](https://s7d2.scene7.com/is/image/TWCNews/Earth-Day-4)

The CLEANR filters are installed inside of Case Western Reserve dormitory laundry rooms. Pennington and Miller hope that’s just the start and their product can change the way washing machines are manufactured in the future.

“What happens when you start filtering out from every single washing machine in Cleveland, in Ohio, in the U.S., in the world? It can make a really big difference," Miller said.

“You can remove 35% of microplastics that are going out into our environment, and it takes less than 30 seconds a week of maintenance," Pennington said. "Our end goal is to show that the technology works in the marketplace and that consumers are willing to fight microplastic pollution. Then we'd hope to work with washing machine manufacturers to integrate our technology into the washing machine.”

You can find out more information including pre-order information on the company website.